Friction

To better understand lubrication concepts, let’s start with the definition of friction. Webster defines friction as the “rubbing of one body against another,” and as “resistance to relative motion between two bodies in contact.” Friction can be beneficial. As we overcome this resistance to motion between two objects in contact, heat is generated. This heat is what warms our hands or starts a fire. Friction is also the principle behind the braking systems we find on our automobiles. In fact, once we were able to get a car moving, there would be nothing to stop it without friction except the effects of gravity or other objects.

However, friction can also be our enemy when heat is generated as the result of friction causing damage. With the contact of two moving parts friction and wear occur in these areas of contact. Thus, it leads to material failures, overheating and the formation of wear deposits.

Although there are many ways to reduce friction, the most common way is through the use of a fluid or semi-fluid material. The key characteristic of such materials is that they are not readily compressible. Fluid and semi-fluid materials allow us to minimize component contact or eliminate contact altogether. Such fluids are commonly referred to as lubricants.

Lubrication Concepts

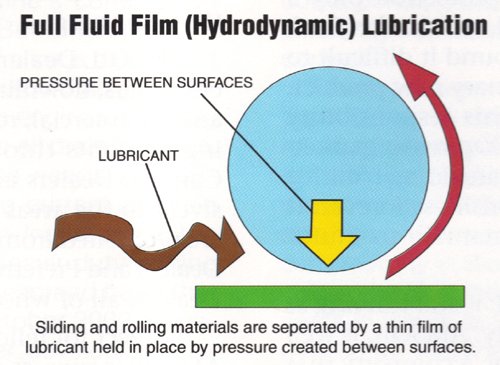

There are three types of lubrication concepts or lubrication situations that can exist between two surfaces separated by a lubricant. Whether or not these situations occur is dependent upon the ability of the lubricant to provide adequate protection to the moving surfaces. When a fluid lubricant is present between two rolling and/or sliding surfaces, a thicker pressurized film can be generated by the movement of the surfaces (at their respective velocities). The non-compressible nature of this film separates the surfaces and prevents any metal-to-metal contact.

The condition in which surfaces are completely separated by a continuous film of lubricating fluid is commonly referred to as Hydrodynamic or Full Fluid Film Lubrication. Although hydrodynamic lubrication is the ideal lubrication scenario, in many situations it cannot be maintained. Hydrodynamic lubrication is limited by the lubricant’s viscosity, the rotation speed or RPM and by component loading. An increase in speed or viscosity increases oil film thickness. An increase in load decreases oil film thickness.

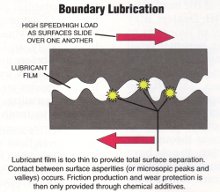

Boundary Lubrication is a condition in which the lubricant film becomes too thin to provide total surface separation. This may be due to excessive loading, low speeds or a change in the fluid’s characteristics. In such a case, contact between surface asperities (or peaks and valleys) occurs.

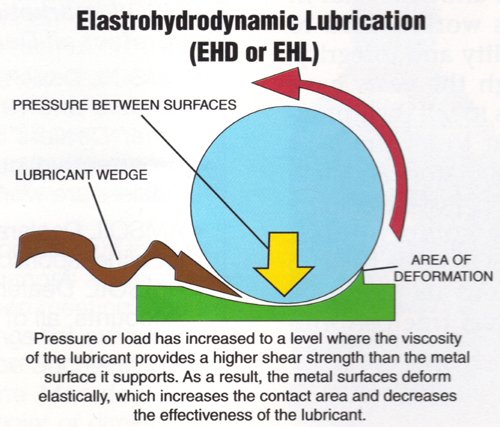

Friction reduction and wear protection is then provided via chemical compounds rather than through properties of the lubricating fluid. The third type lubrication situation is known as Elastohyrodynamic Lubrication (EHD or EHL). This situation occurs as pressure or load increases to a level where the viscosity of the lubricant provides higher shear strength than the metal surface that it supports. As a result, the metal surfaces deform elastically in preference to the highly pressurized lubricant. This increases the contact area and decreases the effectiveness of the lubricant. To minimize friction an effective lubricant should be able to handle the pressures and speeds of the surfaces it will separate.

What Every Lubricant Must do

Though the ability to minimize friction is the number one function of a lubricant, there are other major functions that must be considered.

Clean

A lubricant must maintain internal cleanliness by suspending contaminants or keeping contaminants from adhering to components.

Cool Moving Elements

Reducing friction will reduce the amount of heat that is generated and lower the operating temperature of the components. A lubricant must also absorb heat from the components and transport it to a location where it can be safely dissipated.

Prevent Contamination

The lubricant should act as a dynamic seal in locations such as the piston, piston ring and cylinder contact areas. This minimizes contamination by combustion by-products in the lubricating system. Lubricants are also relied upon to support mechanical seals found elsewhere and to minimize external contamination and fluid loss.

Dampen Shock

The lubricant may be required to cushion the blows of mechanical shock. A lubricant film can absorb and disperse these energy spikes over a broader contact area.

Transfer Energy

A lubricant may be required to act as an energy transfer median as in the case of hydraulic equipment or lifters in an automotive engine.

Prevent Corrosion

A lubricant must also have the ability to prevent or minimize internal component corrosion. This can be accomplished either by chemically neutralizing the corrosive products or by setting up a barrier between the components and the corrosive material.

Components of a Lubricant

Lubricants are generally composed of two groups of materials. The first is a base or stock oil, a fluid that makes up 75 to 95 percent of the finished product. The most commonly used stocks today are derived from petroleum crude oil. These stocks are also referred to as mineral or synthetic oils.

To this, base or stock chemical compounds may be added to enhance or impart new properties to the mineral oil. These compounds are commonly referred to as additives. The use of such special chemical compounds is another way to minimize friction and wear. The main role of these compounds is to offer protection when the lubricating fluid cannot maintain component separation.

The Evolution of Synthetic Oils

As time goes on; the lubrication needs of equipment continue to change. As equipment becomes more sophisticated the demands placed upon the required lubricants become more severe. What may have been a preferred lubricant in the past is likely to be totally unacceptable today. The automotive industry is an excellent example of how demands on equipment have changed. The engines used in today’s cars require significantly more from motor oil than they did only a few years ago. For improved fuel economy, most cars are now using lighter oils, yet the same cars have engines that produce more power per cubic inch of displacement than ever before.

To achieve this power level, designers add turbo chargers that further expose the oils to higher temperatures and greater stress. Requirements for cleaner exhaust emissions contributed to higher levels of contaminants in the oil and also increased the oil’s operating temperature. By reducing the aerodynamic drag of new vehicles, designers inadvertently minimized the amount of air that flows over hot engines and drivetrains that cause operating temperatures to increase still further. Even with all of these changes, designers are still requiring lubricants to last longer than they ever did before, so the demand for synthetic lubricants continues to increase.

How are Synthetic Oils Different?

Although the engineering of each synthetic lubricant varies depending on the particular base stock, synthetics are generally made through a reaction process. This reaction process significantly improves the consistency of the stock and its molecular uniformity. Mineral stocks, on the other hand, are obtained through a process of distillation. Distillation slightly limits the molecular diversity that may exist within the stock but does not completely eliminate nonessential molecular structures. This is important because unnecessary molecular structures produce variations in the stock’s performance.

The ideal lubricant’s chemical composition is one in which the molecular construction is identical throughout, such as in a synthetic base stock. Because of the way synthetic stocks are produced, they are molecularly uniform and contain significantly fewer undesirable materials than a mineral base stock. Molecular uniformity also affects the properties that each type of lubricant possesses. The properties of mineral oils tend to vary due to inconsistencies in the crude from which they are obtained. The properties and performance features of synthetics, on the other hand, are very predictable. Once again, this is due to their molecular uniformity. AMSOIL synthetic lubricants are formulated to take advantage of the superior properties of synthetic base stocks. They provide excellent lubrication and wear protection and have been designed to resist the chemical breakdown processes that limit the service life of conventional mineral-based oils.